Our Services

We know timber; The way it moves, the way it bends, the way it reacts.

Our capabilities span 5-axis CNC machining to heritage woodturning, in-house finishing to laser engraving. An in-house architect, CAD/CAM programmers using Topsolid, and access to Australia's leading designers and makers.

Engaging us early changes outcomes; Specialist advice on the most appropriate timbers to specify, best practices in detailing, the right finish and maintenance for your specific application. Details that account for timber movement, finishes selected for longevity, technical input that prevents problems before manufacturing begins.

Our approach is collaborative, working hands-on with architects, designers, joiners, and builders where material expertise makes the difference.

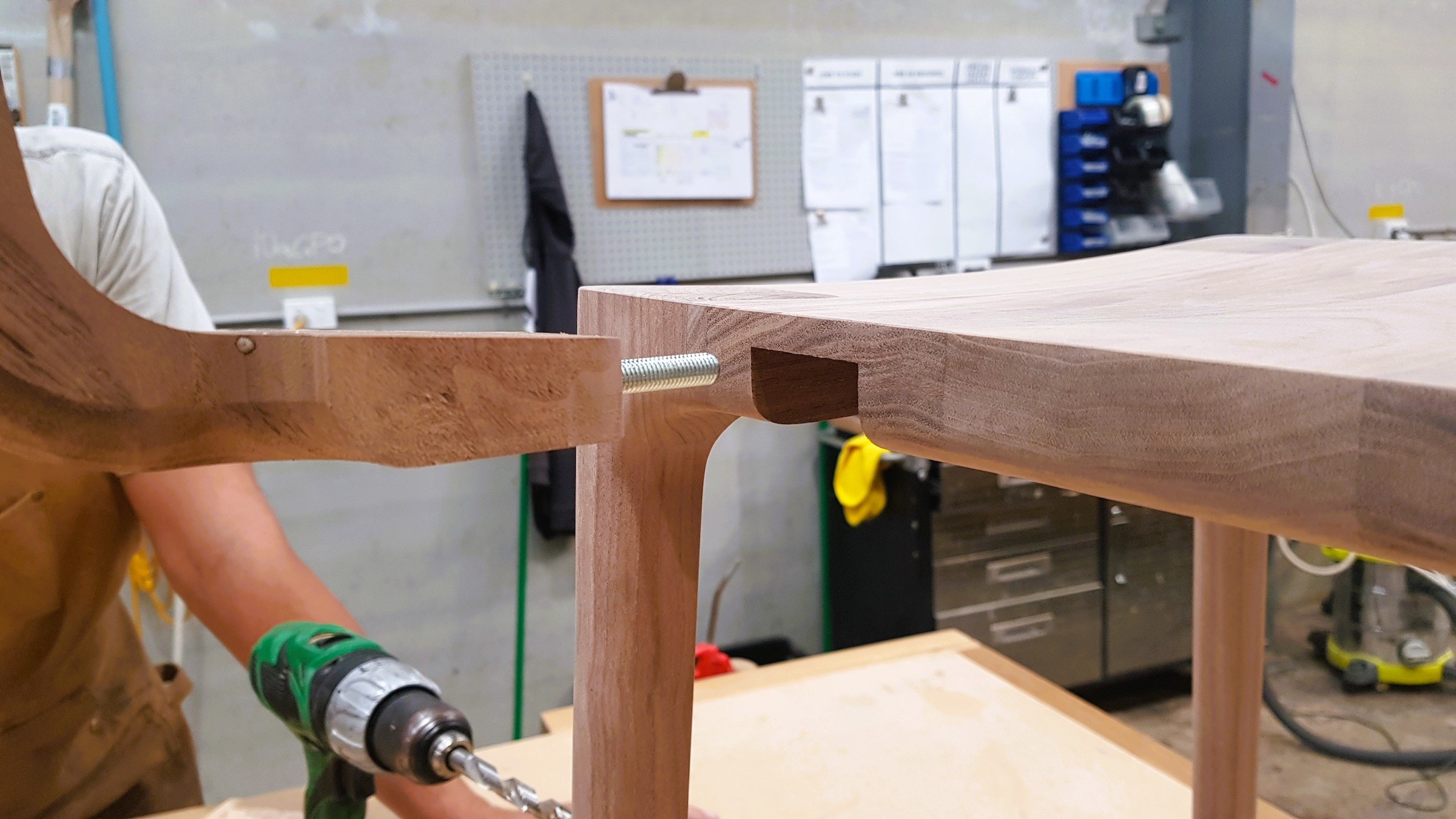

Joinery and Fabrication

We are passionate about delivering high-quality joinery and fabrication that is built to last. With years of hands-on experience across commercial and bespoke projects, we bring a deep understanding of materials, detailing and manufacturing processes to every job.

From concept through to installation, we combine skilled craftsmanship with precision fabrication to produce outcomes that are both functional and refined. Our expertise, attention to detail and commitment to consistency ensure every piece we deliver reflects the standards Evostyle is known for.

Custom joinery

Bespoke one-off pieces

Mass-production furniture + products

Supply only or

Supply and Install

Precision Manufacturing

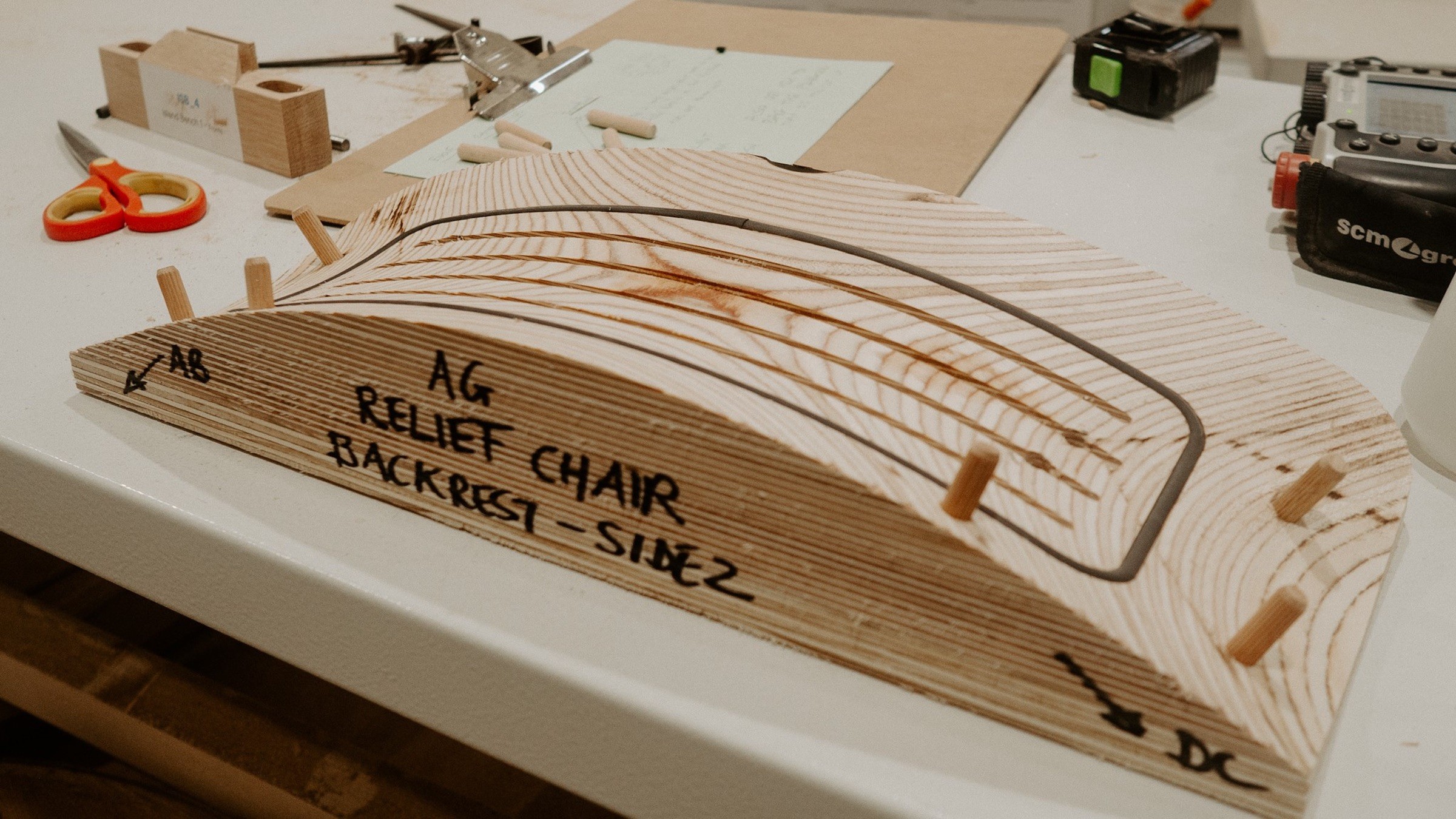

Complex timber fabrication requires understanding of how material behaves; How grain runs, how timber moves, where stress concentrates.

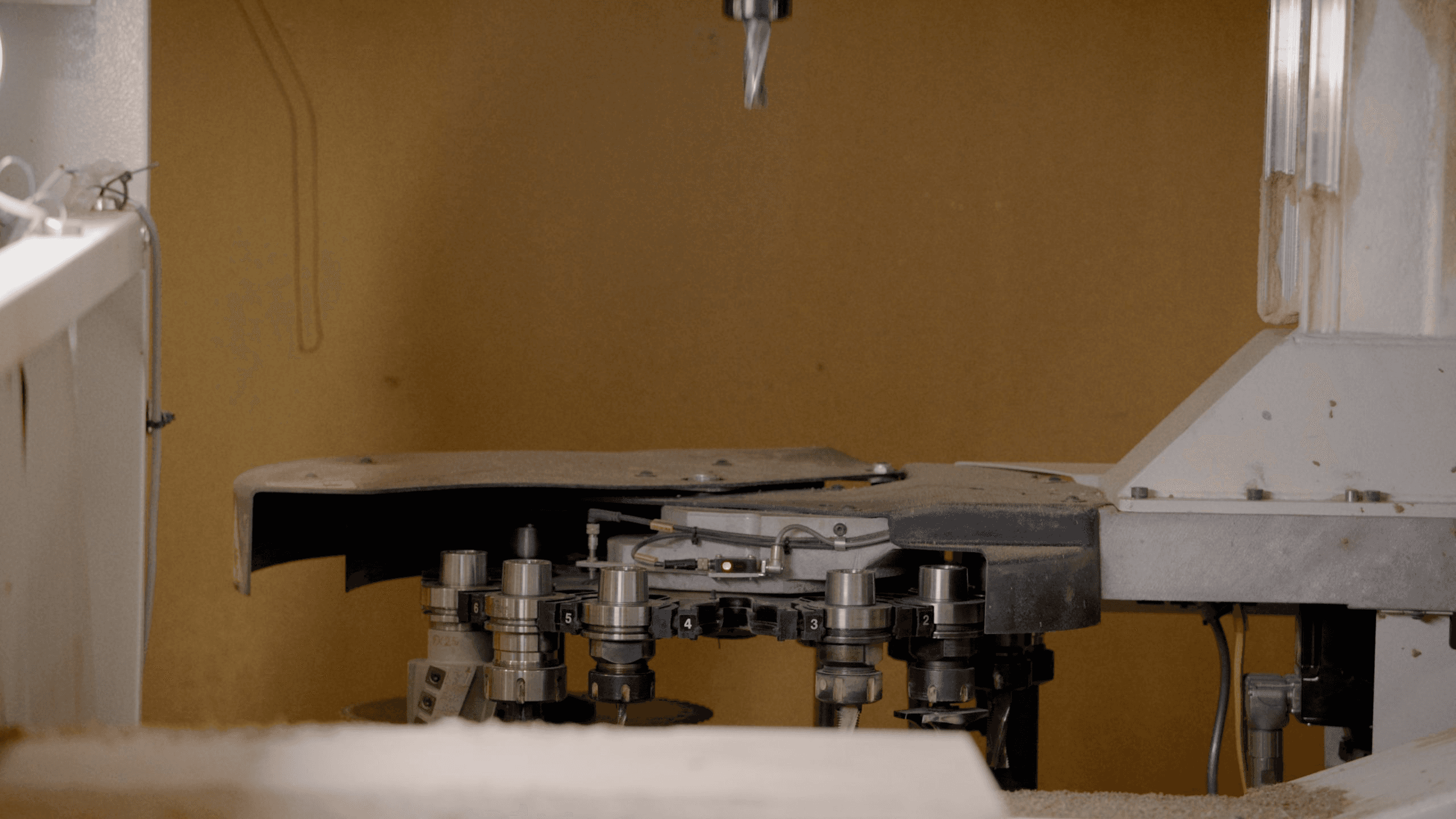

We machine components to tight tolerances across production runs and custom one-offs, using 5-axis CNC capability alongside traditional machine work.

Our programmers use Topsolid, the integrated CAD/CAM software that allows seamless implementation of design changes. Large bed routers handle intricate three-dimensional work. Wide belt sanders, moulders, and custom jigs built for specific projects.

5-axis CNC routers

3-axis CNC routers

CAD/CAM programming (Topsolid)

Custom fabrication & components

Wide belt sanders

Four-head moulder

Jointer / thicknesser

Docking, rip and panel saws

Spindle moulder

Custom jigs and fixtures

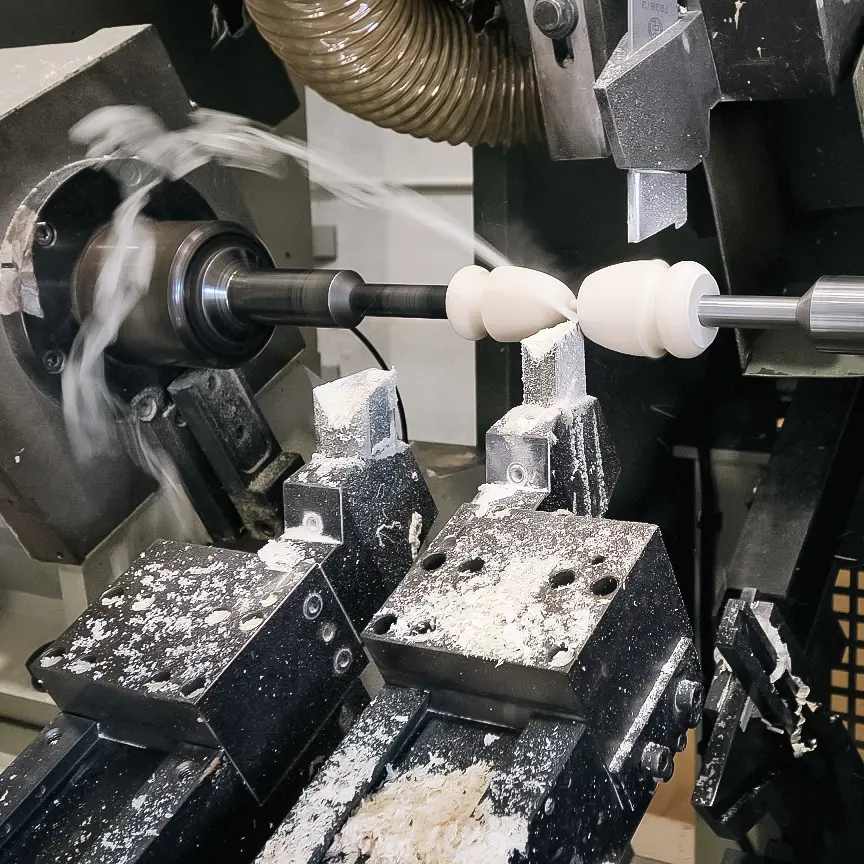

Traditional Crafts

Woodturning has been at our core since the beginning. From delicate custom one-offs to production volumes with exact tolerances, our CNC lathe and skilled hand-turners handle table legs, verandah posts, finials, balusters, and custom profiles.

We work in long lengths and large diameters. Spiral turning and heritage restoration pieces require traditional techniques applied with modern precision - the kind of work that demands both craft knowledge and patience.

Hand lathe

Long bed hand lathe

One-off custom pieces

Mass production turning

Heritage balusters and newel posts

Spirals / Jacobean

Finishing Services

We finish timber products to exacting standards.

Our in-house spray booth is staffed by qualified painters and polishers who handle colour-matching, staining, oiling, waxing, and application of lacquers and polyurethane finishes. On-site finishing reduces lead times and ensures quality control from beginning to end.

We also provide veneering services for complex surfaces where solid timber isn't practical.

Timber preparation is equally precise. Using our four-head moulder, we supply stock DAR to accurate dimensions, fine sanded and ready for installation.

With benchtops as a staple product, we produce wide timber slabs using adhesives matched to each species and application.

Timber preparation and sanding

Spray finishing and polishing

Colour matching and staining

Osmo oil and wax applications

Veneering

Specialist Solutions

The best outcomes begin with early consultation.

Engaging us at the design stage means timber species are selected correctly, details account for movement and grain behaviour, and finishing systems are matched to application. This kind of technical input prevents problems before manufacturing begins.

Our laser equipment handles engraving and cutting up to 10mm for detailed graphics, signage, and decorative elements on solid timber, plywood, and MDF.

We also offer refurbishment services, restoring existing solid timber furniture to original condition through sanding, refinishing, and structural repair where needed.

Design Consultation

Timber specification advice

Laser Engraving & Cutting

Refurbishment Services

Discover what’s possible.

Send us your email address

to be kept informed.

ABN 27 947 460 969